Business

- Business

- Display

Display

You See, We Display

The Display Business Unit develops and provides various optical films for displays based on fine patterning processing/replication technology and polymer material design/formulation technology. We will satisfy the development demands of the ever-changing market through constant research and development and total solutions.

01 Optical Film

"Optical Film" refers to various thin film materials with optical properties used in applications such as smartphone, tablet, laptop, and automotive displays. It is primarily applied in sheet form to display devices. Our Display Business Unit utilizes precision patterning/replication and polymer material design/formulation technologies to develop and provide a wide range of optical films for displays. We strive to satisfy the evolving demands of the market through continuous research and development and total solution offerings.

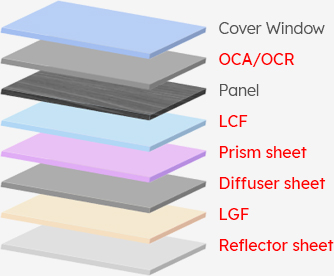

LCD Structure

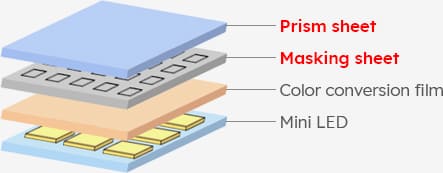

Mini LED Structure

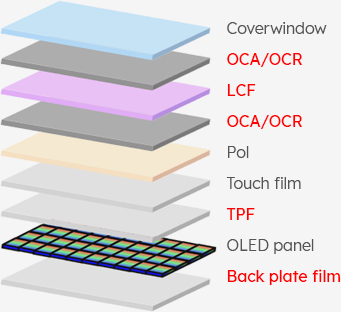

OLED Structure

02 LCD Optical Film

Slim, Narrow-Bezel

YLAS, HLAS-R

Anti Scratch

Anti Scratch

Viewing Angle control

Good Reliability

(OCA,OCR)

Narrow-Bezel

03 Mini-LED Optical Film

Slim, Narrow-Bezel

Slim

Masking Sheet

Super Slim

Masking Sheet

04 OLED Optical Film

Good Reliability

Viewing Angle Control

Anti Static

Good Reliability

05 Auto Optical Film

Slim Narrow-Bezel

YLAS, HLAS-R

Viewing Angle Control

Good Reliability

High luminance

High Reliability

06 Product Spec

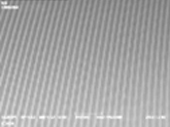

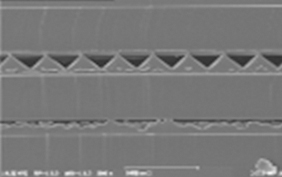

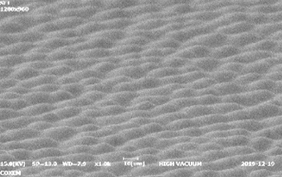

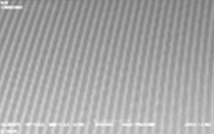

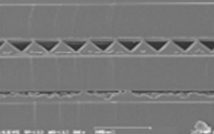

Prism Sheet

| Application | Model | Luminance | Thickness | Remark |

|---|---|---|---|---|

|

HLAS-WJ | 100% |

Mobile series : 65㎛, 93㎛ TPC/NB series : 105㎛, 155㎛ Auto series : 155㎛, 218㎛ |

Normal prism |

| HLAS-TJ | 105% | |||

| HLAS-EJ | 110% | |||

|

XLAS-WJ | 100% |

81 series(MP) : 82㎛ 100 series(MP) : 98 ㎛ 131 series (TPC, NB) : 130㎛ 200 series (TPC, NB) : 180㎛ |

2-in-1 sheet |

| XLAS-TJ | 105% | |||

|

YLAS-TJ | 100% |

151 series : 167㎛ 181 series : 195㎛ |

3-in-1 sheet |

| YLAS-EJ | 105% |

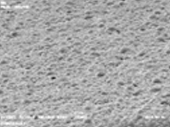

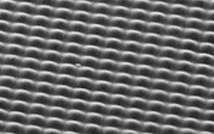

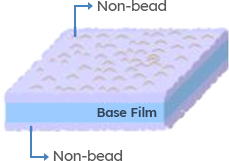

Diffuser Sheet

| Application | Model | Haze | Transmittance | Thickness | Remark |

|---|---|---|---|---|---|

|

DLAS-38S1.5 | 95% ± 5% | 60% ± 5% | 53 ㎛ | Non-Bead type |

| DLAS-50S1.5 | 95% ± 5% | 60% ± 5% | 64 ㎛ | Non-Bead type |

Reflector Sheet

| Application | Model | Haze | Transmittance | Thickness | Remark |

|---|---|---|---|---|---|

|

ALAS-130 | 90% ↑ | 75GU ± 20GU | 129 ㎛ | Non-Bead type |

| ALAS-170 | 90% ↑ | 75GU ± 20GU | 169 ㎛ | Non-Bead type |

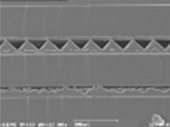

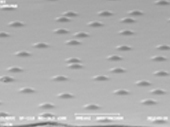

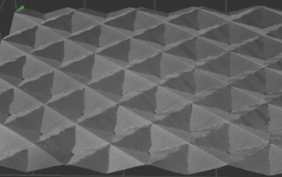

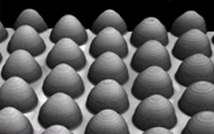

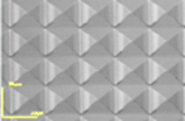

Pyramid Sheet

| Application | Model | Thickness | Haze | Transmittance | Remark |

|---|---|---|---|---|---|

|

XLAS-M150L | 159 ㎛ | 99% ±1% | 17% ± 2% | High Brightness |

| XLAS-M180L | 189 ㎛ | ||||

| XLAS-M240L | 259 ㎛ | ||||

| XLAS-M150H | 159 ㎛ | 99% ±1% | 17% ± 2% | High Shield | |

| XLAS-M180H | 189 ㎛ | ||||

| XLAS-M240H | 259 ㎛ |

LGF

| Application | Luminance | Uniformity | Thickness | Pencil Hardness (Surface Hardness) |

Color Uniformity (△u'v'_A) |

FOS |

|---|---|---|---|---|---|---|

|

Achieving Model-specific Delivery Specifications |

80%±5% | Drawing criteria ±0.03 ↓ |

2B ↑ (PC < LGF ≤ PMMA) |

0.015 ↓ | OK |

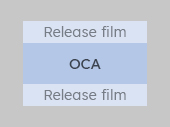

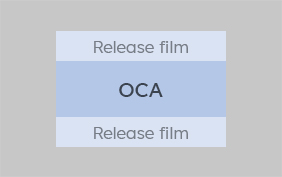

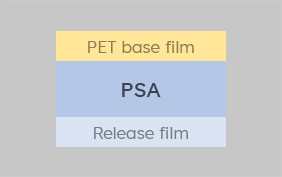

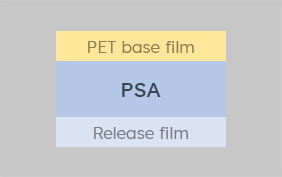

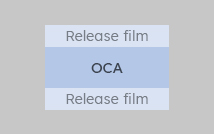

OCA

| Application | Model | Type | Transmittance | Haze | Peel stength @glass | Modulus @25℃ | Ink step Coverage |

|

|---|---|---|---|---|---|---|---|---|

|

LLAS-N | HD4408 | PSA type | 92% | 0.9% | 1.7 kgf/25㎜ | 0.1 MPa | 30% |

| LM1010 | 92% | 0.9% | 1.6 kgf/25㎜ | 0.05 MPa | 35% | |||

| HM1008 | 94% | 0.5% | 2 kgf/25㎜ | 0.11 MPa | 30% | |||

|

LLAS-S | SC3106 | UV curable | 92% | 0.5% |

2.2 kgf/25㎜ (*3.4 kgf/25㎜ after post cure) |

0.32 MPa (*after post cure) |

60% |

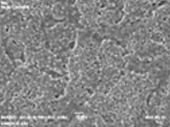

LCF

| Application | ITEM | Haze | Transmittance | Pitch | Thickness | Cut-off | Remark |

|---|---|---|---|---|---|---|---|

|

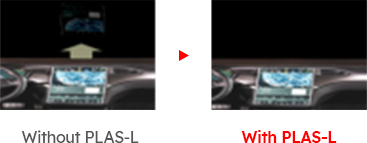

PLAS-L1 | 25% | 44% | 45 ㎛ | 210 ㎛ | ≤6% @45˚ | Louver film with Reflective Polarizer |

|

VLAS | 20% | 67% | 39 ㎛ | 300 ㎛ | ≤6% @35˚ | Louver Film for attaching Cover Glass |

|

PLAS-LM40 | 40% | 43% | 39 ㎛ | 415 ㎛ | ≤8% @35˚ | Louver film with Reflective Polarizer |

| VLAS-LM40 | 40% | 67% | 39 ㎛ | 305 ㎛ | ≤7% @35˚ | Louver Film | |

| VLAS-LV | 22% | 54% | 39 ㎛ | 450 ㎛ | ≤1% @25˚ | Louver Film for CDD (Co Driver Display) |

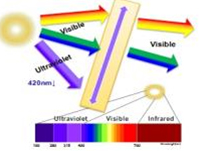

HUD Cover Film

| Application | ITEM | Haze | Visible light polarizing transmittance |

Infrared Transmittance |

Thickness | Remark |

|---|---|---|---|---|---|---|

|

PLAS-C | 2% | 89% | 73% | 375 ㎛ | HUD用 Cover Lens With Reflective Polarizer |

| PLAS-Cv1 | 3% | 81% | 33% | 375 ㎛ | PLAS-C with IR cut-off function |

TPF

| Application | Peel strength @glass |

Haze | Transmittance | Thickness | Surface Resistivity |

|---|---|---|---|---|---|

|

4.0 gf/25㎜ | 0.8% | 92% |

75 ㎛ + 75 ㎛ (PET + PSA) |

Base PET Film Outside : 6x105 Ω PSA : 3x108 Ω |

BF

| Application | Peel strength @glass | Haze | Transmittance | Thickness |

|---|---|---|---|---|

|

2.2 gf/25㎜ | 0.6% | 91% | 75 ㎛ + 25 ㎛(PET + PSA) |

07 Development Direction of Display Business

-

HUD Cover Film

HUD Cover Film- - High Transmittance

- - No Ghost Image

-

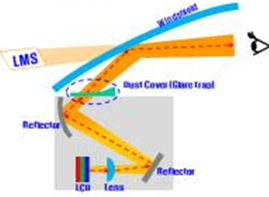

Light Control Film (Louver)

Light Control Film (Louver)- - Optical path control

- - No Ghost Image

-

OCA Film

OCA Film- - Reduced Power Consumption

- - Improved Transmittance

-

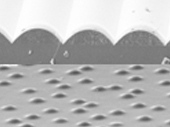

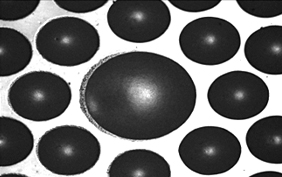

LED Hot Spot Hiding Sheet

LED Hot Spot Hiding Sheet- - Direct Light

- - Local Dimming

-

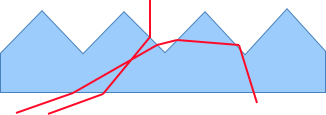

Reverse Prism Sheet

Reverse Prism Sheet- - Light Condensing

- - Viewing Angle Control

-

Prism Sheet

Prism Sheet- - Luminance Enhancement

-

Lami. Sheet

Lami. Sheet- - Luminance Enhancement

-

Reflector

Reflector- - Luminance Enhancement

-

Diffuser

Diffuser- - Masking Ability / Light Diffusing